Home / Vacuuming machines for institutional kitchens

Vacuuming machines for institutional kitchens

For the large-scale packaging of all kinds of food products

Vacuuming machines for institutional kitchens

Are you looking for a vacuuming machine for larger, more production-oriented kitchens, for example in hospitals, hotels of canteens? Depending on your requirements, Henkelman offers a range of different vacuuming machines. This allows you to optimize the workflow, extend the shelf life of fresh products and at the same time prevent food waste.

The advantages of vacuuming for you

Food safety in line with local hygiene requirements

Vacuuming prevents cross-contamination and increases food safety. A deep final vacuum pressure slows down the further development of bacteria. Every machine is designed for easy cleaning and simple daily maintenance, guaranteeing optimal hygiene and productivity.

Longer shelf life, less waste

Henkelman machines vacuum to a vacuum of 99.8%. This prevents food spoilage and therefore reduces food waste as much as possible. Products also have a longer shelf life compared to refrigerating and retain their quality when frozen.

Financial advantages of a Henkelman

Vacuum-sealed products have a longer shelf life. This means you throw away less and therefore save money. A longer shelf life also enables you to better organize your purchasing and make the most of possible purchasing benefits. With proper maintenance (and low maintenance costs) a Henkelman will last for years and retain its resale value.

Efficient workflow

By preparing, portioning and vacuum-packing dishes when you have time, you can work more efficiently when you are busy. This means you can optimize the workflow of your kitchen team and do more with fewer people.

Need help choosing a suitable vacuuming machine?

What functionalities are you looking for in a vacuum packaging machine? Do you want to tenderize products, store them longer or pack liquids? Depending on your needs and budget, one of our dealers can provide you with all the information you need to make the best choice.

Options & accessories

Handy options for your kitchen

Depending on the model and specific type, several Henkelman machines can be upgraded with various optional extras. This can be handy if you want to vacuum-pack specific products, such as soups and sauces (liquid control) or sliced fruit and vegetables (gas flushing, MAP). Using these functions guarantees a perfect vacuuming solution with a longer shelf life and flavour retention. Possible optional extras include:

Soft air

This enables the optimal vacuum packing of sharp or sensitive products without damaging the product or vacuum bag.

Soft air

×Why soft air?

When packing sharp or soft products, soft air ensures that the chamber is aerated gradually and in a controlled way after the vacuuming process. The vacuum bag therefore encloses the product gradually and in a controlled way, ensuring optimal protection.

This makes soft air ideal for packing items such as strawberries, brie and meat products with bone, as well as non-food products such as screws, bolts, electronics etc.

Thermal label printer

Ultra-compact thermal printer (HACCP proof) for labeling products. Only in combination with the Advanced Control System.

Advanced Control System (ACS)

Advanced full color operating system with 20 pre-programmed or user-configurable programs and extra functions for optimal user-friendliness.

Advanced Control System (ACS)

×Why an Advanced Control System?

The full color ACS control panel is a simple operating system with icons and animations for optimal user-friendliness.

The ACS is equipped with 20 pre-set programs. You can name and set these programs, to meet your needs and recipes.

In addition, there are extra functions available such as step vacuum, marinating, tenderizing and also a preserving jar function. The available USB connection can be used to exchange data, and also to connect a (label)printer.

Liquid Control

Stops the vacuuming process when evaporation is detected. This prevents contamination of the chamber, oxidation of the pump, and dehydration and loss of weight

Liquid Control

×Why Liquid Control?

Lowering the pressure in the vacuum chamber causes liquids to boil. Even if they are cold. This is a law of nature. The Liquid Control sensor detects the evaporation that is released. Once boiling point is reached, the vacuum packing machine stops vacuuming and starts sealing. This prevents damage to the product and contamination of the chamber. It also avoids oxidation of the pump.

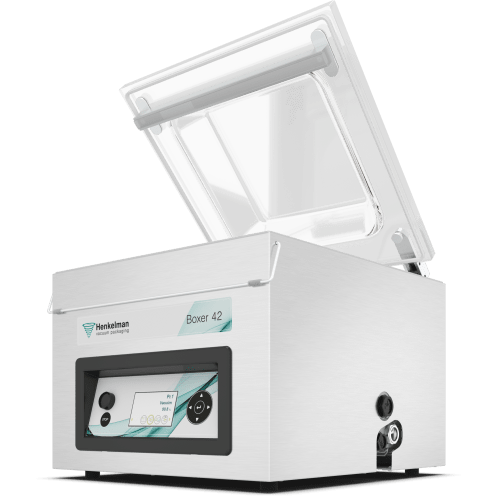

Featured products

Marlin

Model with deep chamber, fitted with transparent plastic lid and powerful pump

Discover the Marlin

Featured products

Falcon Single Chamber Series

With deep aluminum chamber and lid with viewing window, suitable for ESD sensitive products

Discover the Falcon Single Chamber Series

Featured products

Polar Single Chamber Series

Made entirely from stainless steel, with flat work plate as standard

Discover the Polar Single Chamber Series