Double chamber vacuuming machines

As the name suggests, a double chamber vacuuming machine has two chambers in which the vacuuming process takes place. Working with two chambers means that you can prepare products on one side and vacuum products on the other side. This makes it possible to vacuum pack large quantities without having to interrupt your workflow. This type of vacuuming machine is perfect for packaging products for commercial purposes such as the food processing industry.

Which double chamber suits you best?

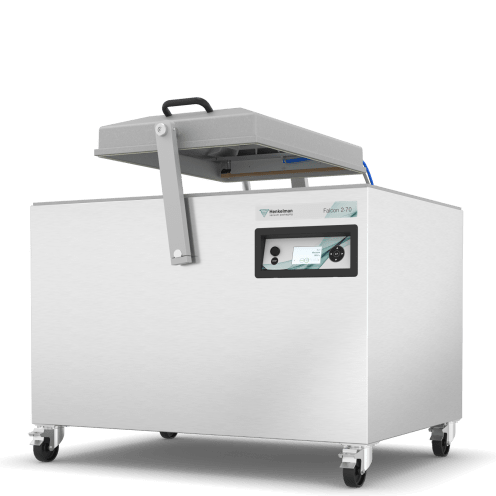

Falcon Double Chamber Series

Two deep aluminum chambers and lid with viewing window

Polar Double Chamber

Made entirely from stainless steel, with flat work plate as standard

Advantages of double chambers

Efficient workflow

Products can be prepared in one chamber and vacuumed in the other, resulting in an efficient workflow.

Maximum productivity

Thanks to the double chambers, you can work continuously. This results in increased productivity.

For larger quantities

Due to the efficient and high productivity of a double chamber, these machines are typically used for packing larger quantities.

Choose the right sealing bar configuration

Choosing the right sealing bar configuration depends on the type of product being packed, the desired productivity, the bags being used and other specific needs. Therefore, get proper advice on which is the best solution for you.

Difference between double and single chambers

Do you need a lot of capacity?

Then a double chamber is best for you. So that you can prepare and vacuum products simultaneously. This increases your production output.

A matter of budget?

Single chamber floor-standing models are cheaper than double chamber ones. But in terms of price, a double chamber model is more cost effective than two single chamber floor-standing machines.

Need a specific sealing bar configuration?

For special sealing requirements, a single chamber floor-standing model has more options and offers extensive sealing bar configurations.