Leak-free packaging that maintains product quality

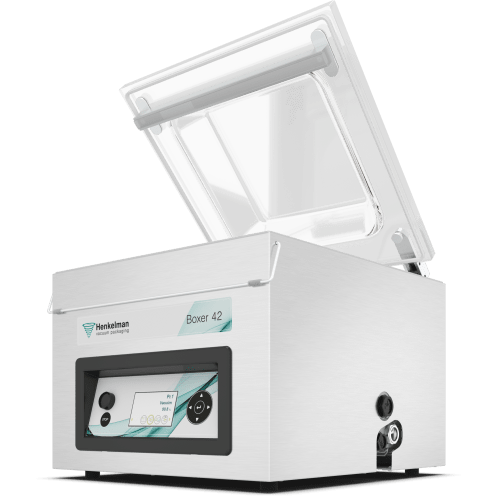

Whether for food preparation, laboratory work or industrial use, vacuum packing liquids offers many advantages. As pressure in the chamber reduces, so does the boiling point of the liquid, which means you need a machine that detects boiling point. This ensures that all liquids are properly packaged and that they retain their quality. It also prevents contamination of the pump. If you want to package soups, sauces, cocktails or other liquid products, choose a Henkelman chamber vacuuming machine with the liquid control option. This gives you endless possibilities.