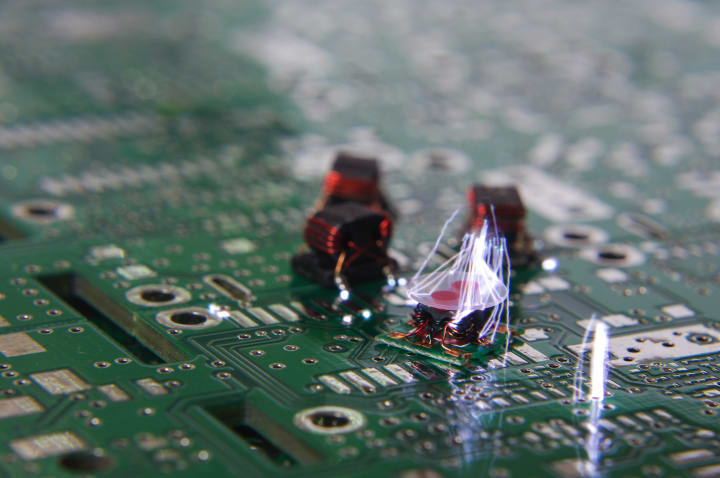

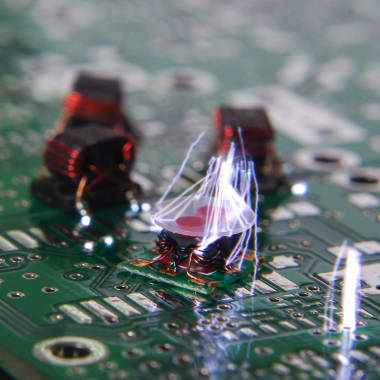

Fully protected

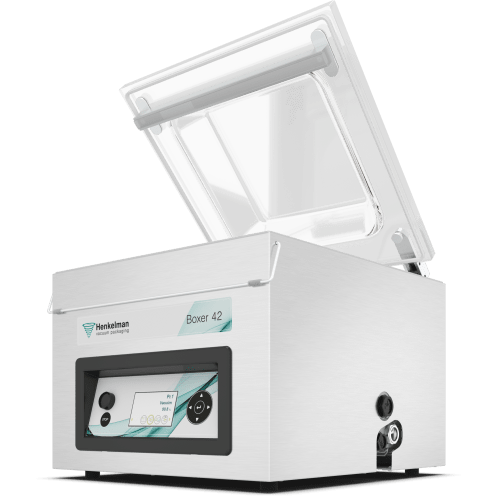

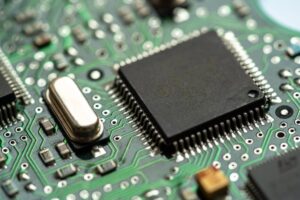

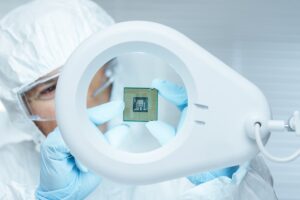

In the world of electronics, where precision and durability are crucial, the vacuum packaging of electronic components offers perfect protection. Whether for printed circuit boards, sensors or chips, packaging these products using a special machine that is suitable for an electrostatic discharge safe environment will protect them against moisture, dirt and dust. Discover the benefits of vacuum packing electronics, where accuracy and functionality come together in advanced packaging.