Table-top and double-chamber vacuum packaging machines are two of the most common types of vacuum packaging equipment on the market. While both machines are helpful in various industries, there are significant differences between them. Table-top vacuum packagings are small, highly portable single-chamber units, while double-chamber packagings are larger, more powerful and built for heavy-duty operation.

Although vacuum packaging machines are most commonly associated with preserving the longevity of food products, they’re also widely used in a range of industries, including medicine, banking, defence and electronics, where they protect and maintain hygienic safety standards for vulnerable goods. If you have products that need to be protected from bacteria, damage, corrosion, or other contaminants, a vacuum packaging machine is one of the most valuable investments you can make.

So, which one best suits your workflow and the nature of your business: tabletop or double-chamber vacuum packaging machines?

Table-Top Vacuum Packaging Machines: Compact & Convenient

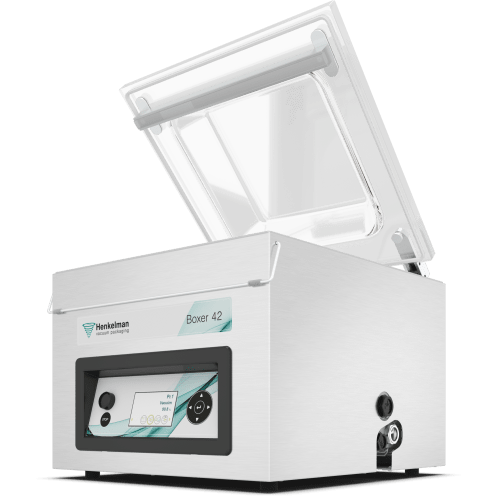

As the name suggests, tabletop vacuum packaging machines are compact enough to fit on a table, counter, or benchtop. They’re also lightweight, highly portable, and affordable, which makes them perfect for small and up-and-coming businesses, as well as those with limited space to work with.

Despite its modest size, a tabletop vacuum packaging is a reliable and powerful machine that perfectly suits the needs of specific businesses, such as cafes, butcher shops, delicatessens, and other specialty and boutique food outlets, as well as catering services and meal prep companies.

Double Chamber Vacuum Machines: Built for High Volume

These large, powerful machines are designed to allow you to prepare products in one chamber and then vacuum them in the other, thereby increasing your output. Two separate chambers share space under a single lid, allowing you to load one chamber while sealing takes place in the opposite one. By allowing two different work cycles to overlap continuously, double-chamber machines increase capacity without compromising quality.

Double-chamber vacuum packaging machines are frequently used in the hospitality industry and other fast-paced commercial environments, where their increased output enables businesses to operate at full speed for more extended periods.

Vacuum Packaging Machine Comparison: Performance & Workflow

No matter which vacuum packaging machine you choose, it’s essential to select a high-quality one that can optimise your performance and workflow. An improved workflow minimises errors and wastage, increases profitability, and keeps customers happy, which makes a world of difference in industries such as hospitality.

Here’s how table-top machines and double-chamber vacuum packaging machines compare in terms of performance and workflow:

Cycle time

Double-chamber vacuum packaging machines aren’t restricted by the inevitable downtime between cycles that comes with table-top vacuum packagings, allowing them to complete more cycles per hour. As you can utilise both chambers simultaneously, double-chamber machines automatically utilise workers’ labour more efficiently.

Liquids and delicates

Both tabletop and double-chamber vacuum packaging machines can handle liquids effectively, as they both feature chambers for this purpose. Chamber machines extract all the air from both inside the vacuum package and the surrounding chamber. This comes in handy when sealing liquids, as, unlike non-chamber machines, chamber packagings pose no risk of sucking the liquids towards the opening of the edge packaging bag.

Energy use

It’s a given that larger packaging machines consume more energy. Fortunately, due to the continuous nature of their operations, double-chamber vacuum packagings utilise this energy efficiently, ensuring that nothing goes to waste.

Cost

Double-chamber vacuum packaging machines almost always have higher upfront costs, which is another reason table-top machines are ideal for start-ups and growing businesses.

Vacuum Packaging Machine Comparison: Upkeep & Space Requirements

Vacuum packaging machines, particularly those used for food, require daily cleaning to prevent contamination. Vacuum machine maintenance also involves regular lubrication and checking of components, such as gaskets and sealing bars. Here’s how table-top and double-chamber vacuum packing machines compare in terms of maintenance and upkeep:

Wear and tear

Because double-chamber vacuum packagings are used more frequently, their pumps are subjected to higher levels of stress and require more frequent and intensive maintenance.

Over time, components such as seal bars and gaskets can develop problems or wear out, eventually requiring replacement. Double-chamber machines naturally come with more components, including more lid gaskets, more complex seal bar arrangements, and overall more parts to inspect.

Cleaning and hygiene

With a smaller surface area and only one chamber, tabletop vacuum packagings are significantly easier to clean and maintain.

Parts availability

With fewer parts to maintain, table-top machines generally have less downtime when problems arise. Double-chamber machines often have larger and more expensive parts that are more expensive or have longer wait times to replace.

Which Is Right For Your Business?

Generally, double-chamber vacuum packaging machines are more suitable for demanding commercial and industrial applications, whereas tabletop machines are better suited for small and boutique businesses with limited space. Some factors that determine which vacuum machine is right for your business include:

Daily number of packs to vacuum package

If you have minimal to moderate vacuum sealing to do, a tabletop model will be suitable. However, if you have a heavy workload (e.g., more than 1,000 packages a day), you’ll want to invest in a double-chamber model.

Product size and type

Both types of machines work perfectly well for the majority of products, but if you’re packaging larger cuts, such as briskets or bulk portions, it’s essential to choose the double-chamber option.

Power and available space

If you’re in a small store or other enclosed space, a tabletop vacuum packaging is both a smaller and quieter option. It’s also perfect for mobile set-ups and shared facilities. A double-chamber machine is far heavier, louder, and requires permanent placement.

Scalability

You can start with a table-top machine and upgrade later. However, if you anticipate your business will grow in the near future, you may decide to prepare early and save money in the long run by investing in a double-chamber option.

Buy the Vacuum Packaging Machine That Suits Your Workflow at Henkelman

Whichever variety of vacuum packaging machine you choose, Henkelman has a sleek, reliable and efficient model to meet your needs. Our tabletop vacuum packaging machines can remove up to 99.8% of air from a package and come in a range of types from the entry-level (but powerful nevertheless) to the upgraded and advanced. These machines are modestly sized to fit on top of a fridge or a counter, but consistently deliver exceptional results.

Henkelman’s double-chamber vacuum packaging machines are equipped with ten operating programs, pump cleaning programs, time control and automatic notifications. Depending on the type of chamber you choose, you can upgrade with extras such as gas flush/MAP packaging, liquid control and an inclined insert plate.

Every Henkelman machine comes with a standard three-year warranty, and parts are available for up to 10 years after production ceases. The Henkelman approach is about more than good machines. We also offer expert advice, high safety standards and quality servicing and support. With an ongoing passion for new technology and innovations, we help you stay prepared for what tomorrow brings.

To find out more about your vacuum packaging options, contact the Henkelman team.