Home / Vacuum packing machines for the meat industry

Vacuum packing machines for the meat industry

Extend shelf life and improve food safety while retaining flavor

Vacuuming machines for the meat industry

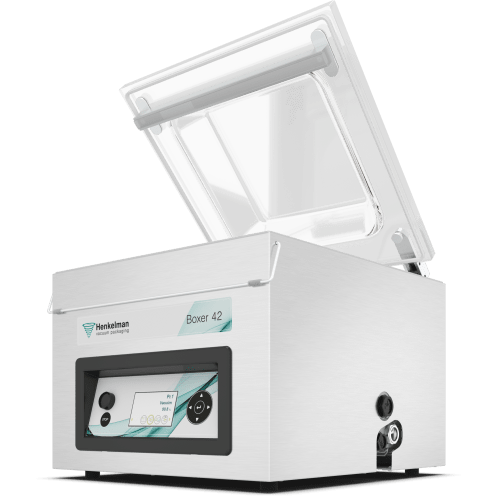

Whether you are packaging fresh or marinated meat, bone-in meat or sliced meat products, a vacuum-sealing machine is indispensable in the meat processing industry. Henkelman offers flexibility with a wide range of different types of machines, capacities, options and additional extras. The reliable machines guarantee continuity, are easy to clean and require little maintenance. You even have the option of a heavy duty version that can vacuum-pack for up to 20 hours a day.

The benefits of a Henkelman for you

Flavor and weight retention

Vacuum-packing food products prevents the growth of aerobic bacteria and therefore extends shelf life without having to add preservatives. Vacuum-packed meat can then mature while retaining weight, flavour and aromas. This also prevents dehydration, freezer burn and mould. Vacuum packed meat has a longer shelf life compared to refrigeration and the products retain their quality when frozen.

High quality

Henkelman machines are specially developed for the food production industry. The machines are easy to clean and require little maintenance, which safeguards continuity. All machines are CE or UL/CSA certified and meet all requirements.

Optimal hygiene

Vacuum-sealing products means that they can be hygienically transported. This enables you to optimize stock by simply storing different products together. It also has benefits for transport.

Create an automatic line

Are you looking to automate the vacuum-packing process as much as possible? Connect a Titaan to a Diptank 200A to create an automatic line.

Featured products

Polar Double Chamber

Made entirely from stainless steel, with flat work plate as standard

Discover the Polar Double Chamber

Featured products

Diptank

For tighter packaging and better presentation of products using shrink-wrap technology

Discover the Diptank

Featured products

Polar Automatic Series

Fitted with automatic lid for improved ergonomics

Discover the Polar Automatic Series

Featured products

Titaan

Fully automatic vacuum packer with automatic outfeed conveyor belt

Discover the Titaan

Options & accessories

Handy packaging options for the meat processing industry

Depending on the model and specific type, you can upgrade every Henkelman with various optional extras and accessories. This can be very useful if you want to vacuum-pack specific products such as marinated bone-in meat, or sliced meat products. By using these functions you are guaranteed a perfect packing solution with longer shelf life and flavor retention. Possible options include:

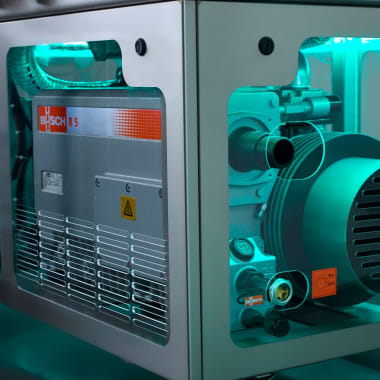

External pump connection

Allows external installation of the pump in separate locations.

External pump connection

×Instead of using the machine’s built-in vacuum pump, you can choose to use an external vacuum pump. This can be installed in a separate room. For industrial applications or situations that demand a more powerful pump, the use of an external vacuum pump can be a valuable option. The main advantage of an externally installed pump is that the source of heat and noise is placed outside the room.

The external pump connection is available on all Henkelman double chamber machines.

Advanced Control System (ACS)

Advanced full color operating system with 20 pre-programmed or user-configurable programs and extra functions for optimal user-friendliness.

Advanced Control System (ACS)

×Why an Advanced Control System?

The full color ACS control panel is a simple operating system with icons and animations for optimal user-friendliness.

The ACS is equipped with 20 pre-set programs. You can name and set these programs, to meet your needs and recipes.

In addition, there are extra functions available such as step vacuum, marinating, tenderizing and also a preserving jar function. The available USB connection can be used to exchange data, and also to connect a (label)printer.

Heavy duty model

Special version of the machine that can be operational for 20 hours per day.

Heavy duty model

×Heavy duty machines can be used for up to 20 hours a day. This model therefore enables an efficient and sustainable packaging process under the most extreme conditions.

The smart construction and choice of robust materials, double seal capacity, heavy pump and aluminum end blocks make this heavy duty solution ideal for packaging processes in the food processing industry.

External conveyor belt

Automatically transports the products