Home / Vacuum packing electronics

Vacuum packing electronics

Protect products from dirt, moisture or damage from external elements

Vacuum packing electronics

Unlike vacuuming food products, electronic components can be damaged because of a static discharge. By choosing a vacuuming machine with ESD prevention (electrostatic discharge), you can be sure that your electronic products are packaged safely. Of course, they are also protected from dirt, moisture and dust.

Advantages of a Henkelman

Optimal protection

Prevents static discharge

Volume reduction

Vacuum-packed products take up hardly any extra space. Perfect for transport and storage.

Special Henkelman machines

Henkelman offers special editions of vacuumpackaging machines for packaging of electronic components that are sensitive to possible electrical discharges that may occur during the packing process.

Machines that are prepared to work in an ESD save environment are standard equipped with a bi-active sealsystem. This is because products sensitive to electrical discharges are commonly packed in aluminium bags.

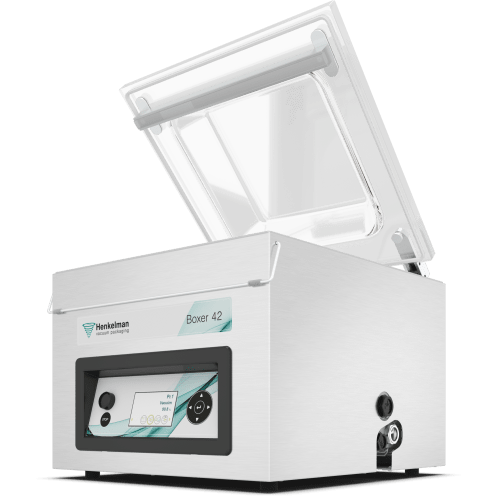

The Falcon 52, Falcon 80 and Boxer 42XL (table top model) are machines that are prepared to work in an ESD save environment.

Need help choosing?

Not every Henkelman is suitable for an ESD-safe environment. The Falcon 52 and the Falcon 80 (floor models) as well as the Boxer 42XL (table model) are suitable for vacuum sealing electronics. Are you curious which machine best suits your needs and budget? We are happy to help you make the right choice.

Options & accessories

Create your made-to-measure Henkelman

The vacuuming machines suitable for electronics (Falcon 52 and 80 single chambers and Boxer 42XL) are equipped with a 10-program memory, time control, bi-active seal and without insert plates.

Electrostatic discharge (ESD)

Special version for packing electronic components that are sensitive to possible static charges that may be generated by the machine and its process.

Electrostatic discharge (ESD)

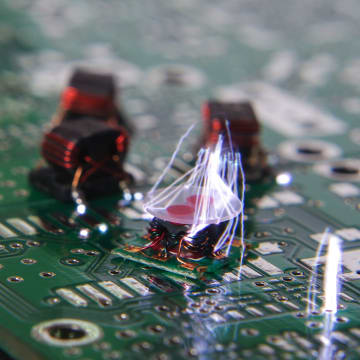

×ESD is the abbreviation for electrostatic discharge. Static charge can be harmful to electronics because they can jump to products with a lower potential. This is harmful to sensitive electronic components and devices. When packaging electronic components and devices such as wafers, chips, motherboards and printed circuit boards or telephones, it is best to choose a machine that is suitable for an ESD-safe environment. These machines are particularly suitable for packaging electronics in an ESD-safe area. Henkelman offers a special range of machines for vacuum sealing these products.

What happens without a machine with ESD?

Damage to semiconductors

Semiconductors such as transistors microchips are extremely sensitive to ESD. A discharge can destroy the thin layers of insulation and cause irreversible damage to these components. ESD also causes non-visible damage to semiconductors. These microscopic defects can also cause failure of electronic devices and components.

Change in electrical properties

ESD can alter the electrical properties of semiconductors. This can cause unwanted variations in voltage, current, and resistance which can lead to malfunctions in the operation of electronic devices. Electrostatic discharge can also cause malfunctions in complex electronic circuits by altering current paths.

Special Henkelman machines

The Henkelman range includes several machines that are suitable for an ESD-safe environment. These are equipped with a bi-active sealing system. This ensures that the aluminium vacuum bags, in which electronics are usually packaged, are sealed on both sides. The Falcon 52 and Falcon 80 (floor models) as well as the Boxer 42XL (table model) are suitable for ESD-safe areas.

Advanced Control System (ACS)

Advanced full color operating system with 20 pre-programmed or user-configurable programs and extra functions for optimal user-friendliness.

Advanced Control System (ACS)

×Why an Advanced Control System?

The full color ACS control panel is a simple operating system with icons and animations for optimal user-friendliness.

The ACS is equipped with 20 pre-set programs. You can name and set these programs, to meet your needs and recipes.

In addition, there are extra functions available such as step vacuum, marinating, tenderizing and also a preserving jar function. The available USB connection can be used to exchange data, and also to connect a (label)printer.

Thermal label printer

Ultra-compact thermal printer (HACCP proof) for labeling products. Only in combination with the Advanced Control System.

Bi-active seal

Seals aluminum and thick vacuum bags on both sides using sealing bars at the top and bottom