In the demanding world of Australian processing and manufacturing, preserving quality isn’t just a goal—it’s a necessity. A premium vacuum packing machine is the cornerstone of effective product management, offering a simple yet powerful way to extend shelf life and secure product integrity.

At Henkelman, we understand that whether you are a high-volume food processor or a precision manufacturer, the objective remains the same: protecting your product. By extracting air and creating a hermetic seal, vacuum packaging equipment safeguards goods against oxidation, spoilage, and external contamination, ensuring that what you pack today retains its value tomorrow.

The Role of Industrial Vacuum Packers in Industry

While a tabletop unit might suffice for a local café, the industrial vacuum packer is the engine room of large-scale operations. These machines are engineered for “heavy-duty” performance, designed to withstand rigorous daily workloads without skipping a beat.

An industrial vacuum packer—such as those found in our heavy-duty Titaan or Polar series—is built for speed, capacity, and reliability. They allow businesses to scale up from manual, single-item sealing to automated, high-output production. With robust construction and powerful pumps, these machines ensure that your packaging process is never the bottleneck in your production line.

Differences Between Commercial and Industrial Models

Choosing the right machine depends on your volume and your specific application. Understanding the difference between a commercial vacuum sealer machine and an industrial model is key to maximising your return on investment.

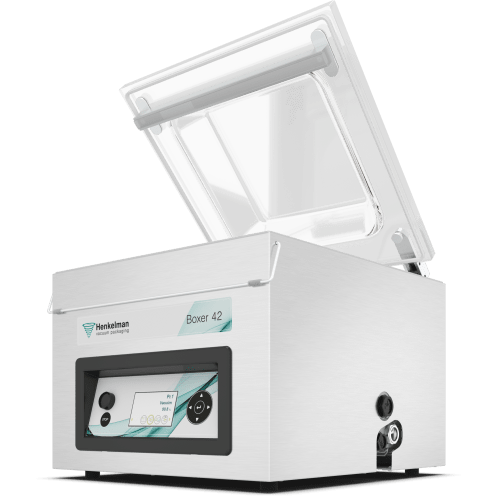

A commercial vacuum packer, like our Boxer or Lynx series, is a compact, tabletop unit. They are perfect for commercial kitchens, restaurants, and retailers where flexibility is key. They handle smaller batches and offer versatility for chefs and front-of-house staff.

In contrast, an industrial vacuum sealer is a floor-standing powerhouse designed for continuous operation. These machines feature larger vacuum chambers, double seal bars for double capacity, and automated lid functions to speed up cycle times. They are built to withstand the intense pressure of 24/7 manufacturing environments, offering advanced features such as conveyor integration and dip tanks.

Key Industries Utilising Industrial Vacuum Packing Machines

The application of a vacuum packaging machine extends far beyond the kitchen. As Henkelman demonstrates, the philosophy of “extracting air, adding value” applies to a diverse range of Australian sectors. Here is how key industries utilise this technology to drive efficiency and protect revenue.

Gastronomy and Catering

For the hospitality sector, from high-end restaurants to hospital canteens, vacuum packing is a dual tool for preservation and creation.

- Sous-Vide Perfection: Professional kitchens rely on chamber vacuum sealers to prepare food for sous-vide cooking. By removing air, heat transfers efficiently through the water bath, ensuring consistent results for meats and vegetables.

- Liquid Control: Advanced models feature Liquid Control sensors, allowing chefs to vacuum-seal soups, sauces, and marinades without the risk of boiling over or spilling within the chamber, significantly reducing marination times from hours to minutes.

- Waste Reduction: By portioning and sealing fresh produce, commercial kitchens can extend shelf life by weeks, directly combating food waste and optimising food costs.

Meat and Fish Industry

This is the heartland of vacuum packing. For abattoirs and fisheries, “heavy-duty” is the keyword. Machines here often run up to 20 hours a day to handle bulk processing.

- Hygiene and Shelf Life: Vacuum sealing prevents the growth of aerobic bacteria. For primal meat cuts or whole fish, this barrier is essential for maintaining hygiene standards from the factory floor to the retailer.

- Product Protection: Features like Soft Air allow the bag to wrap gently around sharp edges—such as bone-in steaks or lobster shells—preventing punctures that would compromise the seal and lead to spoilage.

Fruit and Vegetable Processing

Fresh produce requires a delicate touch; standard vacuum pressure can crush soft fruits or leafy greens.

- Gas Flush (MAP): To solve this, the industry utilises Modified Atmosphere Packaging (MAP). The machine injects an inert gas mix (typically Nitrogen or Carbon Dioxide) after the vacuum cycle but before sealing. This creates a protective cushion around the product, preventing crushing while inhibiting the oxidation that causes browning. It is the industry standard for keeping pre-cut salads, apple slices, and berries crisp and market-ready.

Electronics

In the electronics sector, moisture and dust are critical threats. However, standard vacuum packing can risk static damage.

- ESD Prevention: Henkelman’s specialised industrial packers are designed for ESD (Electrostatic Discharge) safety. They allow manufacturers to package sensitive circuit boards, wafers, and chips in anti-static bags.

- Corrosion Control: By creating an oxygen-starved environment, these machines prevent the oxidation of copper and silver components during storage and international shipping.

Industrial Manufacturing and Engineering

Beyond electronics, heavy industry relies on vacuum packing to protect precision-engineered metal parts. A slightly rusted gear or turbine blade can render a valuable component useless.

- Rust Prevention: By eliminating oxygen, the process effectively halts corrosion on machined parts and tools without the need for messy oil coatings.

- Kitting: Manufacturers use these machines to ‘kit’ small parts—such as bundling bolts, gaskets, and components together. This ensures that assembly teams or customers receive complete, dust-free sets ready for immediate use, preventing loss and assembly errors.

Retail and Artisan Producers

For consumer-facing businesses like artisan cheesemakers, butchers, and farm shops, presentation is as vital as preservation.

- Professional Presentation: Table-top vacuum packers allow these businesses to offer professional, leak-proof packaging that signals quality to the customer.

- Odour Isolation: Vacuum packing ensures that pungent products, like matured cheeses or marinated skewers, can be stored without drying out or cross-contaminating other foods in a consumer’s refrigerator.

Non-Food and Logistics

Efficiency is currency in logistics. Vacuum packing bulky items—such as textiles, bedding, or even sneakers—drastically reduces volume.

- Volume Reduction: Compressing soft goods can reduce shipping volume by significant margins, allowing businesses to optimise container loads and warehouse space.

- Protection: Beyond size, vacuum sealing protects goods from dust, dirt, and “container rain” (condensation) during transport. For delicate items, Soft Air technology ensures the pressure change does not deform the product.

Currency and Archival Documents

Banks, museums, and government bodies utilise vacuum technology for security and preservation.

- Secure Storage: Vacuum-sealing bundles of banknotes or important identity papers protects them from moisture, silverfish, and environmental degradation.

- Tamper Evidence: The hermetic seal acts as an immediate visual guarantee of integrity, ensuring that secure packages remain unopened until they reach their destination.

Benefits of Using Industrial Vacuum Sealers

Investing in a high-quality vacuum sealer packaging machine drives efficiency and profitability.

- Improved Quality and Freshness: By eliminating oxygen, products maintain their original texture, taste, and appearance for longer.

- Cost Reduction: Less waste translates directly to the bottom line. Industrial packing also allows businesses to purchase raw materials in bulk and store them safely, taking advantage of market fluctuations.

- Enhanced Product Protection: A robust seal protects against freezer burn, cross-contamination, and physical damage during transit.

Precision Sealing With Henkelman Industrial Vacuum Packaging Machines

At Henkelman, our machines combine functional design with top-tier durability. Our industrial range is equipped with the latest technology to suit your specific needs. From our Advanced Control System (ACS), which allows for programmable packing cycles, to Soft Air technology that protects delicate products and vacuum bags, we provide more than just a machine—we provide a solution. With a standard 3-year warranty on our equipment, Henkelman Australia offers peace of mind alongside performance.

Whether you need a fully automatic Titaan for a production line or a robust Polar for heavy loads, we have the technology to keep your business moving. To find the right setup for your facility, explore our range of automatic industrial vacuuming machines or learn more about whether vacuum packing is the most suitable option for your industry. If you need advice tailored to your specific industry, please contact our Australian team because we are here to help.