The ability of vacuum packaging machines to protect and preserve food and other items makes them a valuable investment in various industries. In commercial kitchens, vacuum packaging equipment preserves the quality of food supplies and helps prevent wastage. For supermarket delis and butcher shops, they keep food fresh and impeccably presented. These versatile machines also benefit businesses in the pharmaceutical, electronic, cosmetic and manufacturing industries, serving purposes such as protecting delicate components or maintaining sterility.

Vacuum packaging is a method that involves removing all air from a plastic film package prior to closing it, creating an airtight seal. Vacuum packaging machines use a powerful pump to extract all the air from the bag (and sometimes the chamber around it) before sealing it shut with a heated sealing bar. Vacuum packaging helps preserve food in its peak condition, keeping it fresh for longer and helping you and your business avoid food waste and unnecessary expenses.

With various types of vacuum packaging machines available on the market, it’s essential to select the right one that suits the needs of your business.

Henkelman helps companies in hospitality, retail and non-food related operations across the world operate more efficiently with high-quality vacuum packaging machines. We can provide you with advice that takes into account your products, workflow and budget to help you find the machine that best serves your needs.

Selecting the Right Machine: Factors to Consider

There are several key factors to consider when choosing a vacuum packaging machine, and some of the most important are:

Your packaging needs

Every business has its own specific packaging requirements that include the product type (foods, liquids or non-food related items), the volume of your operations and the dimensions and weight of your packaging. All of these factors influence the kind of machine that would best serve your environment.

Brand reputation

When the future success of your business depends so heavily on your vacuum packaging machine, it’s important to choose a machine from a brand known for quality and reliability. It’s also important that the machine complies with industry standards and regulations, something brands that prioritise quality are more likely to do. Check the warranties associated with vacuum packaging equipment models and the availability of replacement parts.

Operational efficiency and easy maintenance

Vacuum packaging machines that are easy to use, clean and maintain make for more efficient operations and save you time and energy. In busy high-volume industries, this makes a major difference, especially during peak periods. Machines that are designed to be accessible, easy to clean and maintain help to keep downtime to a minimum.

Scalability

Consider your future needs and how you plan to scale your business, and choose a machine that can grow with you. Planning for scalability early can save you the extra effort and cost of upgrading later on. Commercial-grade machines that are efficient and durable with automated functions to reduce labour are excellent for prioritising scalability.

Features and specifications

The material of your vacuum packaging machine matters. Stainless steel is strong, long-lasting and easy to clean. Other features that matter include the capacity of the vacuum pump, the length of the seal bar, the control panel and its features and whether or not there’s a gas flush option. You may also need to consider whether or not you need a machine that can handle liquids, e.g. for sous vide cooking.

Understanding Vacuum Packaging Machine Types

There are multiple varieties of vacuum packaging machines on the market, each catering to customers with different needs. Some forms of vacuum packaging machines that are likely to benefit your business include:

Table-top vacuum packaging machines

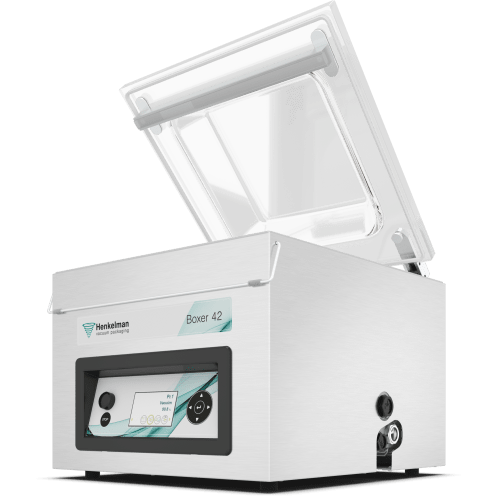

A table-top machine is a compact option perfect for smaller companies and those with limited space. It’s also a more affordable choice if you don’t need to vacuum pack every day. Like the name suggests, a table-top machine sits nicely in a spot such as a counter-top or on the top of a refrigerator.

Floor-standing single-chamber packaging machines

With sturdy designs and powerful pumps, floor-standing single-chamber machines are ideal for intensive usage and processing high volumes of packaging. Powerfully built with robust pumps, they’re ideal for demanding daily usage in both the food industry and other sectors.

Double-chamber packaging machines

Double-chamber machines keep your workflow efficient when you have large volumes of packaging to do. With two chambers to work with, you can prepare products on one side and vacuum them on the other, achieving enhanced productivity levels.

Automatic industrial vacuuming machines

You can create your own production line by combining a single or double-chamber automatic industrial vacuuming machine with a dip tank. After vacuuming, an external conveyor belt transports products directly to a dip tank for brief immersion, then proceeds to the next step. This automated process means a higher production output, a lighter physical workload and less physical effort required.

Choosing Vacuum Packaging Machines by Industry

Along with various other factors, the type of industry you’re in influences the style of vacuum packaging machine that would benefit you the most.

Table-top machines are best suited for small-scale operations and those with limited space. Small food businesses like cafes and delis, as well as those in the pharmaceutical and electronic industries, can benefit a great deal from these compact machines.

Floor-standing single-chamber machines are more powerful units suited to more dynamic, high-production environments, such as supermarkets, retail outlets and busy catering companies.

From food service to food production to catering, any industry that involves high quantities of food production can benefit significantly from the increased output of double-chamber vacuum packing models.

Fully automated industrial vacuuming machines are ideal for any industry that requires high-speed, large-scale food production with manual labour at a minimum. Examples include packaging facilities, large-scale food manufacturers and high-volume supply chains.

Get the Right Vacuum Packaging Machine for Your Business

If you’re still not sure which vacuum packaging machine is the right one for your business, the best way to find out is to contact the team at Henkelman directly.

Henkelman has smart vacuum packaging solutions that add value as they remove air, with our vacuum packing machines removing up to 99.8% of all oxygen from packaging. A Henkelman unit helps prevent food spoilage, cross-contamination, freezer burn and mould, increasing food safety.

Each Henkelman machine meets both local and worldwide quality standards, including safety, health and environmental regulations. It also includes a three-year warranty with parts available for up to 10 years after production has ceased.

Henkelman’s selection of vacuum packaging machines includes high-quality tabletop, floor-standing, double-chamber, and automatic industrial vacuuming machines, as well as dip tanks, all manufactured to the highest possible standards.

Our commitment to the success of your business doesn’t end with our machines. Henkelman also offers expert advice and first-rate customer service and support to help our customers succeed. We have a worldwide dealer network, so wherever in the world your company is located, you can always contact us if you need assistance.

For queries, advice and technical support, get in touch with the Henkelman team.