The better a food is packaged, the longer it lasts and the safer it is to eat. So it’s no surprise that vacuum packaging is all around us, so common that it slips by unnoticed. You’ll find it in the meat or dairy aisles of your local supermarket, in the cold room if you work in the hospitality industry, and even in your own freezer. It’s one of the most effective ways to preserve the taste, freshness and nutritional value of food.

Vacuum sealing is a simple process, as long as you have the right technology. The food is placed inside a plastic sleeve, and the edge of the sleeve is then placed in a vacuum sealer machine. The sealer sucks the air completely out before sealing the packaging to create an impenetrable barrier.

Vacuum packaging improves the shelf life of food, prevents it from contamination and exposure to the elements and keeps its natural taste, colour and texture intact.

This process has tangible benefits for both those in the food service industry and regular consumers. Food waste is a very common but preventable problem. Knowing how to increase the shelf life of cooked food means less of it ends up being discarded. Vacuum sealing extends the lifespan of highly perishable items and makes it easier to save money by buying in bulk.

The science behind vacuum packaging and how it increases the shelf life of food is covered in this article. Henkelman explores the process behind food deterioration and the effects of vacuum packaging on its shelf life. If you’ve been looking for an effective way to keep your food in optimal condition, this is our guide to how vacuum packaging can meet your needs.

Microbial & Chemical Mechanisms: Why Food Lasts Longer

Food spoilage is primarily caused by two main factors: microbial contamination and chemical changes.

Animals, plants and microorganisms have a symbiotic relationship in nature. Bacteria, moulds, and yeasts use our food as a source of nourishment to fuel their own growth. As they feed on nutrients, they break down the food and produce various by-products, including organic acids and sulphur compounds. Some of these microorganisms are toxic and can cause illness. For example, Salmonella, which commonly lives in chickens, poses a danger in raw chicken and eggs. Microbes can grow very quickly in food at warmer temperatures between 5°C and 60°C, which is why adequate refrigeration increases the shelf life of food.

Chemical changes like enzymatic degradation and lipid oxidation (free radical reaction between oxygen and fatty acids) also cause the breakdown of foods. Like the growth of enzymes, this process is hastened by higher temperatures and tempered by refrigeration.

In some circumstances, these processes are desirable. Blue cheese gets its distinct flavour from edible moulds, while aged beef’s tenderness is the product of enzymatic breakdown. However, for the most part, it’s best to avert food spoilage for as long as possible.

Material Matters: The Role of High-Barrier Films

High barrier films are multilayer packaging materials designed to protect food from elements that hasten its spoilage. They form a protective layer around foods to keep away moisture, which fuels the growth of bacteria and mould. They also keep out oxygen, light and humidity, helping to prevent oxidation and drying out.

Vacuum packaging seals food in airtight, high-barrier films and protects it from dirt, dust and other elements that can hasten spoilage. Vacuum packaging extends the shelf life of your food up to five times longer than other forms of packaging, such as containers or plastic bags.

Types of Vacuum Packaging and Their Applications

There are two main types of vacuum packaging: chamber and non-chamber, as well as other related methods that approach vacuum packaging in a different way:

Chamber vacuum sealing

Chamber sealing machines have a chamber in which the vacuum bag and its contents are placed. The machine vacuums air from the entire chamber before sealing the bag, creating equal pressure both inside and outside of it. This is a fast method of sealing that’s also suitable for liquids and moisture-rich foods, which is why it tends to be the preferred choice in commercial kitchens, food service businesses and other high-volume environments.

Non-chamber/external sealing

Non-chamber vacuum packaging machines remove air only from the bag, keeping the rest of the machine open to the elements. External vacuum sealing machines are more compact, more affordable and more suitable for home use. They are unsuitable for liquids.

Modified atmosphere packaging/gas flush

MAP packaging protects and preserves shelf life by adding a preservative gas, typically a mixture of nitrogen, argon, and carbon dioxide, with some additional oxygen. This gas flush preserves the shelf life of products such as lettuce, crisps, and cooked fish, preventing their discolouration.

Skin packaging

Skin packaging involves placing a product on a tray or board and draping a rigid film over it that uses vacuum pressure to cling to the product’s shape. This form of vacuum sealing not only extends the shelf life of food, but it also makes it more presentable for display in supermarkets, butchers’ shops, etc.

Liquid control

Liquid control is a technique used in vacuum sealing for liquids or high-moisture foods. Lowering the pressure in a vacuum chamber causes even cold liquids to boil. The Liquid Control sensor detects the evaporation, and once the boiling point is reached, the machine stops vacuuming and begins to seal instead. This prevents chamber damage, product contamination and pump oxidation.

Extending Shelf Life across Food Types

Extending the shelf life of food isn’t a one-size-fits-all approach. Different food types require different vacuum packaging strategies to preserve freshness, reduce waste, and maintain quality.

Meat & Poultry

Fresh or cooked, red meat, chicken, and game all benefit from vacuum sealing. By removing oxygen, vacuum packaging slows bacterial growth, prevents freezer burn, and enhances product safety. It also allows red meats to age naturally, improving tenderness and flavour. Whether you’re a butcher, wholesaler, or food processor, Henkelman machines ensure optimal storage and presentation for extended shelf life without compromising on quality.

Seafood

Seafood is highly perishable and sensitive to temperature and handling. Vacuum sealing helps retain natural moisture, prevents odours from spreading, and protects delicate fillets from damage during transport, for value-added products like marinated fish or crustaceans, a liquid control function on a vacuum packaging machine ensures clean, precise sealing without spillage, perfect for busy fishmongers or commercial kitchens.

Fruit & Vegetables

Fresh produce is prone to wilting, mould, and spoilage when exposed to air. Vacuum packaging slows down this degradation, extending shelf life and reducing waste. Leafy greens, chopped veg, and even berries can be vacuum-packed, especially if the machine has a Soft Air function, which ensures gentle handling of fragile or sharp-edged foods. For added protection, Modified Atmosphere Packaging (MAP) can be used to replace oxygen with a controlled gas mix, keeping produce fresher for longer.

Cheese & Dairy

Vacuum packaging prevents cheese from drying out or absorbing external odours. It’s ideal for both soft cheeses, such as Brie, and hard cheeses, like Cheddar. It also keeps grated or sliced dairy products fresh and ready for retail. Some cheeses continue to mature under vacuum, enhancing their depth of flavour while remaining protected from spoilage.

Liquids, Sauces & Marinated Foods

Wet or saucy foods often present a challenge in standard vacuum systems, but a machine with an advanced Liquid Control feature allows you to seal soups, sauces, and marinades without mess safely. This ensures hygiene, extends shelf life, and allows for easy portioning and storage. It’s ideal for ready meals, catering, and food service applications.

Bakery & Dry Goods

Vacuum packaging isn’t just for fresh food; bakery items like bread, biscuits, and pastries stay crisp and mould-free for longer in vacuum packs. For dry goods such as nuts, grains, or coffee beans, vacuum sealing helps preserve aroma and flavour while preventing exposure to humidity or pests.

Extend the Shelf Life of Your Food with Henkelman

If you’re looking for vacuum packaging to extend the shelf life of your food products, Henkelman is happy to help. We provide top-quality vacuum packing solutions to those in the hospitality, food service and even non-food-related industries to help them preserve the quality of their goods and combat food waste.

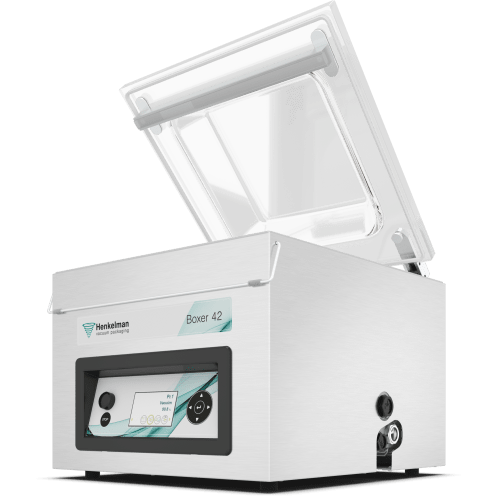

Our vacuum packaging machines include tabletop, floor-standing, double-chamber, and automatic industrial models for all types of businesses and operation sizes. From small mobile kitchens to large-scale operations, we offer efficient, high-quality machines from leading brands that ensure your perishables are vacuum-packed to the highest standards. Got questions? Get in touch with Henkelman.