In the fast-paced world of industrial packaging, efficiency is key. With so much depending on getting the right packaging to market quickly, reliably, and cost-effectively, businesses should always be looking for ways to improve. One of the most impactful innovations in this space has been the rise of the auto vacuum sealing machines. These machines are transforming the way products are packaged by ensuring faster, more consistent results that help businesses maintain high standards of quality while saving time and money.

In this article, we’ll explore what an industrial vacuum sealing machine is, the challenges they address and why they’re such a game-changer for industries looking to streamline their packaging processes.

What Are Auto Vacuum Sealing Machines?

An auto vacuum sealing machine is a piece of equipment designed to automate the vacuum sealing process. These machines remove air from packaging and create a vacuum-sealed, airtight environment around the products. Typically, these machines are used in industries like food production, pharmaceuticals, and logistics because they help to extend shelf life, prevent contamination, and protect valuable goods during storage and transit.

Unlike manual sealing methods, which rely on labour-intensive processes, an auto industrial vacuum sealing machine automates the entire process, from vacuuming out the air to sealing the bags. This leads to faster processing times, greater consistency, and improved product protection.

The beauty of these machines lies in their simplicity. Products are placed into a vacuum bag, the air is extracted, and the bag is sealed with precision, often in mere seconds. The result is a tightly sealed package that minimises exposure to air, moisture, and contaminants.

The Challenges of Industrial Packaging

Industrial packaging presents unique challenges that businesses must overcome to stay competitive. While packaging is a crucial aspect of any product, it comes with its own set of hurdles:

Preserving freshness and quality

For many industries, particularly food and pharmaceuticals, product quality is non-negotiable. Air, moisture, and exposure to environmental factors can significantly shorten a product’s shelf life, leading to spoilage, contamination, or degradation of quality. Manual packaging methods often fail to achieve the level of airtight sealing necessary to properly preserve products, especially over extended periods.

Inconsistent results

In a manual packaging line, human error is inevitable. Whether it’s the variation in how tightly a bag is sealed or how much air is removed, these inconsistencies can lead to subpar packaging results. Inconsistent seals can compromise the safety, freshness and overall integrity of the product, leading to unnecessary waste or consumer complaints.

Slow processing speeds

Manual packaging is time-consuming. When you have high volumes of products to package, relying on manual labour is simply not sustainable. Slow processing times lead to bottlenecks, extended production times, and potentially missed deadlines, all of which affect a company’s bottom line.

Rising operational costs

Inefficient packaging methods translate to higher operational costs. These come from wasted materials, excessive labour, and increased energy consumption. The longer the packaging process takes, the higher these costs become.

How Auto Vacuum Seal Machines Improve Packaging Efficiency

Auto vacuum sealing machines offer a simple, yet highly effective solution to these common challenges. By automating the vacuum sealing process, these machines help businesses significantly improve their packaging efficiency. Here’s how:

Fast processing speeds

By automating the vacuum sealing process, an industrial vacuum sealing machine drastically increases productivity. Unlike manual methods that require multiple steps and human oversight, these machines can package products quickly and consistently. The result is faster processing times and a much more efficient production line.

Consistent, high-quality seals

Automation removes the risk of human error. Each vacuum seal is performed to the exact same standard, ensuring uniformity and consistency in every package. Whether you’re packaging food, medical products, or anything in between, you can rely on the machine to consistently produce high-quality, airtight seals.

Improve product preservation

By creating an airtight seal, auto vacuum packaging machines protect products from air, moisture, and contaminants, extending the shelf life and ensuring quality. For food products, this could mean fresher goods that last longer on store shelves. For pharmaceuticals or medical devices, it ensures products remain sterile and safe for use.

Cost savings

While the upfront cost of an industrial vacuum sealing machine might be a concern for some, the long-term savings are considerable. By reducing labour costs, minimising material waste, and improving efficiency, you can quickly see a return on your investment. By reducing spoilage and waste, you can further lower their operational costs.

Scalability

As demand grows, so do packaging needs. Fortunately, auto vacuum packaging machines are designed with scalability in mind. These machines can handle increased production volumes without sacrificing quality, making it easy to adapt to growing demands. Plus, with adjustable settings, businesses can easily modify the machine to handle different products or packaging formats.

Space and energy efficiency

Modern vacuum sealing machines are designed to fit seamlessly into existing production lines. They’re compact, space-saving, and easy to integrate into most factory layouts. Additionally, many machines are energy efficient, helping to reduce electricity usage and lower operating costs.

Finding the Right Vacuum Sealing Machine for Your Business

Not all vacuum packaging machines are built the same. To ensure you select the right equipment for your business, you need to consider several key factors:

Product type and size

Different products require different sealing solutions. Whether you’re packaging small food items, bulkier goods, or sensitive products like medical supplies, it’s essential to choose a machine that is suited to your specific needs. Some machines are optimised for small items, while others are designed for larger or more fragile goods.

Production volume

If you’re running a high-volume operation, you’ll need a machine that can keep pace with demand. A high-capacity industrial vacuum sealing machine is designed for continuous operation, ensuring that your production line remains efficient and uninterrupted.

Vacuum strength and seal quality

Not all vacuum sealing machines provide the same level of vacuum strength or sealing quality. Ensure the machine you select has adjustable settings that enable you to fine-tune the vacuum strength and sealing pressure according to your product’s specific requirements.

Ease of use and maintenance

Look for machines with intuitive controls and simple maintenance routines. This will help reduce downtime and keep your operation running smoothly. Machines that are easy to clean and maintain are especially important in industries like food packaging or pharmaceuticals.

Durability

In an industrial environment, durability is key. Choose a machine that’s built to last, capable of withstanding the rigours of continuous use. A high-quality machine ensures that you won’t have to deal with frequent breakdowns or costly repairs.

Buy A Henkelman Auto Vacuum Sealer To Improve Efficiency

In an increasingly competitive market, finding ways to improve packaging efficiency is crucial. Auto vacuum sealing machines have emerged as a vital solution by increasing speed, consistency, and product preservation.

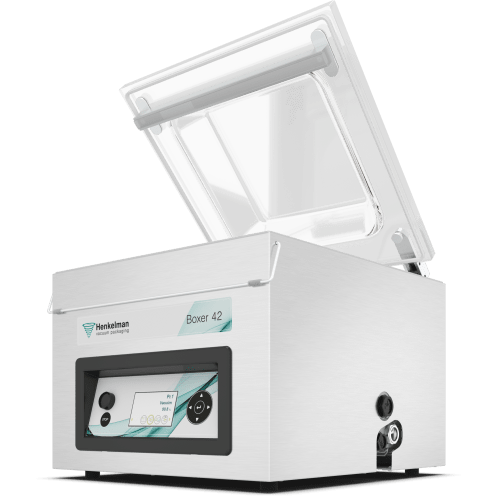

When it comes to industrial vacuum sealing, Henkelman is a trusted name in the industry. Our fully automatic vacuum sealing machines are designed with performance and reliability in mind so that they streamline packaging processes, improve efficiency and reduce costs. With advanced technology and precise vacuum control, and durable construction, our auto vacuum sealing machines provide the perfect balance of speed, quality, and longevity.

Whether you’re packaging food, medical products, or other goods, Henkelman offers a range of solutions tailored to meet the unique needs of your business. By investing in a Henkelman vacuum packaging machine, you’ll be well on your way to improving the efficiency of your production line, preserving products, and cutting operational costs.

To learn more about our vacuum packaging solutions, contact the Henkelman team.