For any chef, food manufacturer, or production manager who has worked with a standard chamber vacuum packer, the scenario is all too familiar. You place a bag of premium veal stock, a delicate consommé, or a complex marinade into the chamber. You close the lid, press start, and watch.

For the first fifteen seconds, the process looks normal. The bag tightens, the air is extracted, and everything seems calm. Then, in the blink of an eye, the liquid inside the bag begins to bubble violently. Before the operator can hit the emergency stop button, the bag effectively erupts. Your stock is now coating the inside of the lid, the seal bar is soaked, and the bag is half-empty.

The result is a triple loss: wasted product, a mess that requires significant downtime to clean, and a compromised seal that will likely fail in storage.

For decades, the industry standard solution was the “Watch and Wait” method. A staff member had to stand directly in front of the machine, staring through the lid, finger hovering over the stop button, trying to guess the exact millisecond before the boil-over occurred. It was inefficient, inaccurate, and stressful.

Enter Henkelman Liquid Control.

This intelligent feature, available on our machines equipped with the Advanced Control System (ACS), is not merely a convenience upgrade; it is a fundamental shift in how professionals handle liquids in a vacuum environment. By automating the detection of the boiling point, Henkelman allows businesses to achieve the perfect vacuum for liquids—automatically, every single time.

The Physics of the “Cold Boil”

To understand why Liquid Control is such a vital asset, we must first respect the physics of the vacuum chamber. It is a common misconception that liquids only boil when heated. In reality, the boiling point of a liquid is directly related to the surrounding atmospheric pressure.

We are taught that water boils at 100°C. However, this is only true at standard atmospheric pressure (approximately 1013 millibars). Inside a Henkelman chamber, the goal is to remove 99.8% of that air. As the pressure inside the chamber drops, the boiling point of the liquid drops with it.h

- At standard pressure, water boils at 100°C.

- At 20 millibars (a standard vacuum level), water will boil at approximately 17.5°C.

This phenomenon creates a dangerous window for operators. A bag of soup that feels cool to the touch (around 25°C) will start boiling violently long before the machine reaches its maximum vacuum potential. This “cold boil” is not cooking the food, but the physical reaction is identical to a pot on a stove: rapid expansion of vapour. This vapour forces the liquid out of the bag, ruins the seal area (making a hermetic seal impossible), and sprays food particles into the vacuum pump intake.

The Solution: Sensor Intelligence Over Timer Guesswork

Standard vacuum packers typically rely on time control. The operator sets the cycle to run for 30 seconds. The machine has no way of knowing if the chamber contains a dry steak, a block of cheese, or a litre of water. It simply pulls air until the time runs out. If the liquid reaches its boiling point in 20 seconds, the machine continues to pull for another 10 seconds of chaotic boiling.

Our Liquid Control replaces this guesswork with a high-sensitivity sensor.

How the Sensor Works

The Liquid Control sensor actively monitors the vapour pressure inside the chamber during the cycle. It is specifically calibrated to detect the “phase change”—the precise moment the liquid begins to evaporate and turn into gas.

- Detection: As the vacuum cycle progresses, the pressure drops. When the liquid reaches its boiling point relative to the current pressure, it releases a burst of vapour.

- Reaction: The high-sensitivity sensor detects this sudden spike in humidity and vapour density.

- Action: The machine immediately stops the vacuum pump and initiates the sealing cycle.

The result is a cycle that stops at the maximum possible vacuum for that specific liquid temperature, without a single drop being spilled. The bag remains full, the chamber remains clean, and the seal is perfect.

The Three Pillars of Value for Australian Businesses

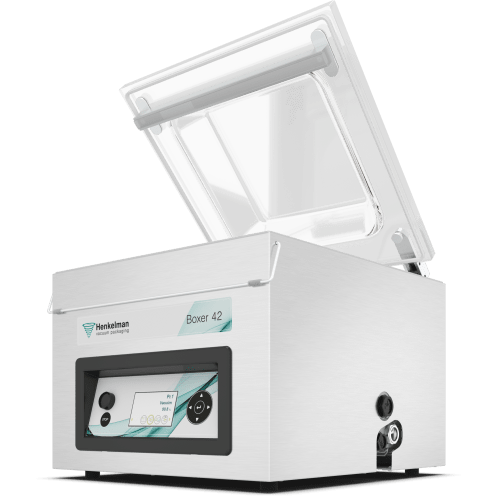

Why should a commercial kitchen or food processor invest in a machine with Liquid Control (such as the Boxer 42 ACS or the Aero 35)? The return on investment is built on three pillars: Operational Speed, Hygiene, and Asset Protection.

1. Operational Efficiency: The “Set and Forget” Workflow

In a busy Australian commercial kitchen, labour is the highest operational cost. Without liquid control, packaging liquids is a “one-to-one” task: one staff member must monitor one machine to prevent accidents. This is dead time.

With liquid control, the process becomes fully autonomous. A chef can place four bags of sauce in the chamber, close the lid, and walk away to chop vegetables, check the pass, or plate a dish. The machine will detect the limit for those specific bags and seal them automatically.

- Batch Consistency: Whether the sauce is chilled to 4°C or sitting at ambient 20°C, the machine adjusts the cycle automatically. The operator does not need to change settings.

- Multi-Tasking: Staff can confidently multitask, knowing the machine will not create a mess while unattended.

2. Hygiene and Food Safety Compliance

A boil-over is a significant hygiene risk. When liquid sprays inside the chamber, it settles in the crevices of the lid gasket, under the stainless steel lift-deck, and around the seal beams. If not cleaned meticulously, this organic matter becomes a breeding ground for bacteria.

A “wet seal” is a failed seal. If the sauce pushes into the sealing area during the vacuum cycle, the heat bar boils the liquid trapped between the plastic layers instead of melting the plastic together. This creates microchannels through which air can re-enter the bag, leading to spoilage. Liquid control keeps the liquid in the bag and keeps the seal area dry, ensuring the integrity of the package and the safety of the food.

3. Pump Protection: The Hidden Cost Saver

This is the factor most buyers overlook until it is too late. The heart of your Henkelman vacuum packer is the Busch pump. It relies on specialised oil to lubricate and seal the internal vanes.

When a liquid boils in the chamber, that moisture does not simply vanish—it is sucked directly into the pump intake.

- The Emulsion Effect: When water vapour mixes with pump oil, it creates an emulsion (resembling mayonnaise). This sludge loses its lubricating properties, leading to friction and overheating.

- Corrosion: Moisture inside the pump leads to rust on the internal metal components when the machine is turned off.

- The Cost: A seized pump due to moisture damage is a major repair bill.

By stopping the cycle before violent boiling occurs, liquid control drastically reduces the amount of moisture vapour entering the pump. It keeps your oil cleaner for longer, extends the intervals between maintenance services, and significantly prolongs the lifespan of the machine.

Applications: Beyond Just Soup

While preventing spills is the primary function, Liquid Control unlocks advanced culinary and preservation techniques for specific sectors.

The “Cook-Chill” Production Kitchen

For catering companies, aged care facilities, and hospitals producing bulk soups, stocks, and curries, rapid cooling is essential for HACCP compliance. Liquid control allows kitchens to vacuum pack liquids while they are still warm (though not piping hot). Vacuum packing removes the insulating air, allowing the bags to be plunged into an ice bath or blast chiller where they cool down significantly faster than they would in a standard tub. This ensures the product passes through the bacterial “danger zone” (60°C to 5°C) in record time.

The Bar Scene: Alcohol Infusions

Australian mixology is world-class, and vacuum infusion is a staple technique. Bartenders use vacuum machines to infuse spirits with fruits, herbs, or spices instantly. This often involves liquids with high alcohol content. Alcohol has a lower boiling point than water, meaning it evaporates even faster under vacuum conditions. Liquid control allows bartenders to pull a precise vacuum on a gin or vodka infusion without boiling off the alcohol, ensuring the potency and flavour profile remain intact while achieving rapid extraction.

High-End Sous Vide Preparation

Marinating meats often involves wet marinades containing wine, vinegar, or soy sauce. To get the best texture, chefs want the highest vacuum possible to open the meat’s pores. Liquid control allows the chef to push the vacuum to the absolute physical limit—getting maximum penetration—without the risk of the marinade ruining the seal or contaminating the chamber.

Investment in Consistency with a Henkelman Machine

In the high-pressure environment of the Australian food industry, equipment needs to be smarter than the problems it solves. A vacuum packer that requires constant supervision is not an asset; it is a liability.

Henkelman’s Liquid Control transforms the most difficult packaging task—liquids—into the easiest. It eliminates the mess, secures the seal, and protects the expensive pump mechanism from damage. It allows your staff to focus on creation rather than observation.

For any business that handles stocks, sauces, marinades, or infusions, the upgrade to an ACS-equipped machine with Liquid Control is not just a luxury—it is a calculation of efficiency.

Stop watching the bubbles. Start saving time.

Discover the Henkelman models featuring the Advanced Control System (ACS) and Liquid Control today. Visit our machines page or contact our team for a demonstration.