Cooking sous-vide

Vacuum cooking

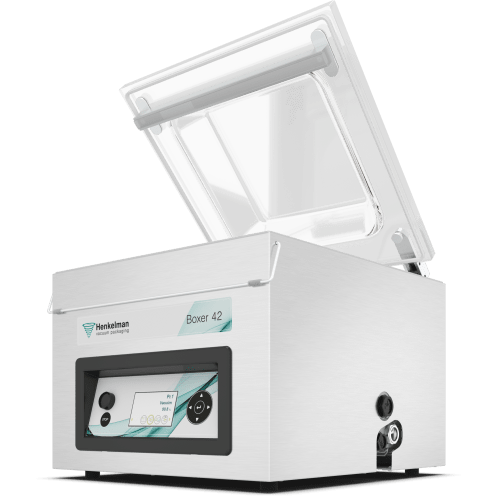

Sous-vide literally means ‘under vacuum’: a technique whereby vacuum-packed food is slowly cooked at a relatively low(er) and well controlled temperature. It offers several benefits that help to preserve the natural flavours and nutritional value of the ingredients. In combination with a good vacuum sealing machine, it ensures the preservation of quality, flavour and unprecedented precision and consistency on the plate. Discover your culinary possibilities with a Henkelman.

Step-by-step plan for sous-vide cooking

1. Mise-en-place

Prepare and portion your products. Put them in a vacuum cooking bag together with flavour enhancers if required. Select the right program and vacuum-seal the ingredients.

2. Cook

Place the vacuum-sealed product in a warm water bath and cook it at the right temperature. Choose the required time, depending on your ingredients

3. Cool

If you are not serving your product immediately, it must be cooled before refrigerating. This can be done naturally by allowing the product to cool outside the fridge, or by using a blast chiller.

4. Serve or store

When you are ready to serve, you can start plating. Or you can store (refrigerate) the product for later use.

Advantages of sous-vide cooking

Preservation of flavour and texture

By slowly cooking ingredients in a very precise, controlled way, they retain their naturally occurring flavours, juices and nutrients.

Consistent, high-quality results

Cooking sous-vide at a low, controlled temperature reduces the risk of over or under cooking. So you will always serve the best cooked ingredients, time and time again. Day after day.

Flexible timing

Sous-vide gives chefs the flexibility to prepare and cook dishes in small and large quantities without overcooking them. The food can remain in the warm water bath until it is ready to be used or served.

Useful options and functions with sous-vide cooking

If you want to use your Henkelman to prepare ingredients for sous-vide cooking, there are several functions that make it even easier to vacuum-seal your ingredients.

Advanced Control System (ACS)

Advanced full color operating system with 20 pre-programmed or user-configurable programs and extra functions for optimal user-friendliness.

Advanced Control System (ACS)

×Why an Advanced Control System?

The full color ACS control panel is a simple operating system with icons and animations for optimal user-friendliness.

The ACS is equipped with 20 pre-set programs. You can name and set these programs, to meet your needs and recipes.

In addition, there are extra functions available such as step vacuum, marinating, tenderizing and also a preserving jar function. The available USB connection can be used to exchange data, and also to connect a (label)printer.

Liquid Control

Stops the vacuuming process when evaporation is detected. This prevents contamination of the chamber, oxidation of the pump, and dehydration and loss of weight

Liquid Control

×Why Liquid Control?

Lowering the pressure in the vacuum chamber causes liquids to boil. Even if they are cold. This is a law of nature. The Liquid Control sensor detects the evaporation that is released. Once boiling point is reached, the vacuum packing machine stops vacuuming and starts sealing. This prevents damage to the product and contamination of the chamber. It also avoids oxidation of the pump.

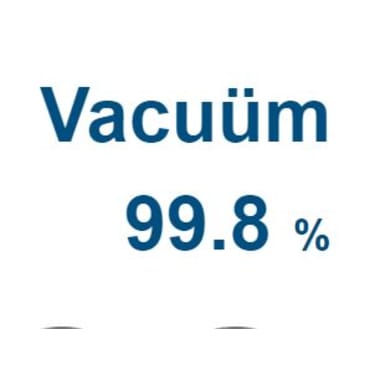

Sensor control

Detects the vacuum pressure and automatically stops the process when the preset vacuum percentage is reached

Sensor control

×Sensor control

For a consistent and guaranteed vacuum result

Always an optimal cycle

Vacuuming machines with sensor control use a pressure sensor to measure when a pre-set vacuum percentage has been achieved. This differs from more traditional vacuuming processes whereby sealing begins automatically once a certain time cycle is complete. In this case you cannot be sure that the desired final vacuum result has been created. To put it simply: with sensor control, the desired final vacuum result is always achieved. Regardless of the volume and even with varying quantities and products. Sensor control is available as an option on several ranges, but the function is also a standard part of the Advanced Control System and on the Aero and Aura machines.

Operating sensor control

Sensor control is very easy to use. Place the product or several products directly in the chamber. Then turn on the machine and manually set the desired final vacuum result or choose a pre-set program. Close the lid and initiate the vacuuming process. Once it detects the correct vacuum percentage, your Henkelman machine will automatically proceed to the next step in the vacuuming process.

Inclined insert plate

Positions the vacuum bag at an angle. This makes it easier and more efficient to vacuum pack fluids and powders.

Which machine for sous-vide cooking?

Henkelman offers a wide range of vacuum sealing machines so that you can easily vacuum-pack all your ingredients. The type of product, the size and number of portions per day will determine which machine suits you best. Do you need advice?