In the commercial kitchen or food processing plant, the vacuum packer is often viewed as a blunt instrument. Its primary job is simple: remove the air, seal the bag, and stop the clock on spoilage. For solid items like cured meats, cheese blocks, or cryovac steaks, this “hard vacuum” is perfect.

But what happens when your product is fragile? What if you need to package a pre-mixed garden salad, a loaf of gluten-free bread, or marinated chicken kebabs? A standard vacuum cycle would crush the lettuce into a paste, flatten the bread, and distort the kebabs.

This is where Gas Flush, technically known as Modified Atmosphere Packaging (MAP), becomes the most valuable tool in your arsenal.

For Australian businesses ranging from artisan bakeries to large-scale vegetable processors, Henkelman’s Gas Flush technology bridges the gap between shelf-life extension and product presentation. It allows you to protect the structure of your food while still fighting the biological causes of decay.

Understanding the Technology: What is Gas Flush (MAP)?

Gas Flush, or Modified Atmosphere Packaging (MAP), is a process used in vacuum packaging where the ambient air inside a package is replaced with a specific mixture of inert gases (typically Nitrogen, Carbon Dioxide, or Oxygen). This gas mixture creates a protective atmosphere that inhibits bacterial growth and prevents oxidation, while simultaneously acting as a protective cushion to prevent delicate foods from being crushed.

How the Process Works

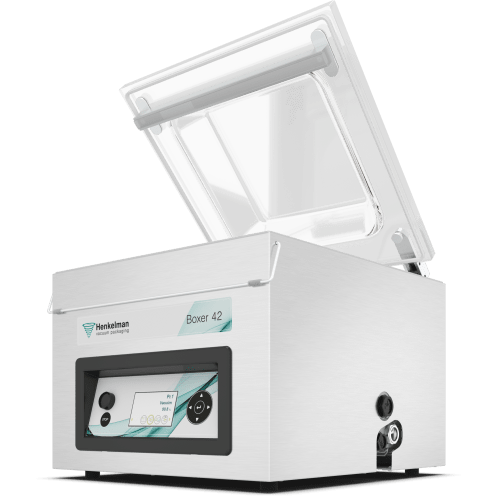

In a Henkelman chamber machine equipped with the Gas Flush option (available on models like the Boxer, Marlin, and Polar series), the cycle involves three distinct steps:

- Evacuation: The vacuum pump removes 99.8% of the atmospheric air (and oxygen) from the chamber and the bag.

- Injection: Before the seal bar lifts, the machine injects the pre-determined gas mixture into the bag through nozzles.

- Sealing: The bag is hermetically sealed, trapping the gas mixture inside.

The result is a package that looks “puffed up” or relaxed, rather than tight and brick-like. The product inside remains loose and visually appealing, but it is just as protected against spoilage as a hard-vacuumed steak.

The Chemistry of Freshness: Understanding the Gases

To utilise MAP effectively, it helps to understand what is actually going into the bag. The gas mixture is usually supplied by an external tank (or gas mixer) connected to your machine. The specific blend depends entirely on what you are packing.

Nitrogen (N2): The Cushion

Nitrogen is the primary component of most MAP mixtures. It is an inert, odourless, and tasteless gas.

- Function: Its main role is to act as a “filler” or a stabiliser. Because nitrogen does not dissolve in water or fat, it stays in the bag and maintains the volume of the package.

- Application: It creates the “pillow” effect that protects potato chips, salad leaves, and delicate baked goods from being crushed during transport or stacking.

Carbon Dioxide (CO2): The Inhibitor

Carbon Dioxide is the heavy hitter for preservation.

- Function: CO2 dissolves into the liquid and fat phase of the food, creating a slightly acidic environment that inhibits the growth of aerobic bacteria and mould.

- Application: It is essential for extending the shelf life of bakery products, hard cheeses, and oily fish. However, too much CO2 can cause packaging to collapse as it dissolves into the food (known as “snapping”), so it is usually balanced with Nitrogen.

Oxygen (O2): The Colour Enhancer

Wait, isn’t the goal to remove oxygen? Usually, yes. However, in specific applications, oxygen is added back in.

- Function: Oxygen maintains the myoglobin in red meat, keeping it that bright, consumer-preferred cherry red. It also allows fresh fruits and vegetables to “breathe” at a controlled rate, preventing anaerobic spoilage.

- Application: Primarily for retail-ready red meat and specific fresh produce types. Note: Using high-oxygen mixtures requires a special “Oxygen Protection” pump upgrade on your machine to prevent explosion risks.

Key Industries Transformed by Gas Flush

Why should an Australian business invest in a machine with MAP capabilities? The return on investment comes from waste reduction and the ability to access new markets.

The Fresh Produce Sector (Fruit & Veg)

Australia has a massive appetite for convenience—pre-cut salads, stir-fry mixes, and prepared fruit bowls.

- The Problem: Vacuuming lettuce breaks the cell walls, turning it brown and slimy instantly. Leaving it in a regular bag leads to rapid wilting.

- The Solution: A MAP mix (typically low O2, balanced O2/N2) slows down the respiration rate of the vegetables. This keeps apple slices crisp and white, and salad leaves crunchy and green for days longer than standard storage. This enables green grocers and processors to prep days in advance, smoothing out labour spikes.

Bakeries and Patisseries

- The Problem: Baked goods go stale due to moisture loss and starch retrogradation, or they grow mould. Freezing alters the texture, and standard vacuum packing flattens croissants into pancakes.

- The Solution: A Nitrogen/Carbon Dioxide flush creates a protective atmosphere that halts mould growth without crushing the product. You can package gluten-free loaves, par-baked breads, or delicate pastries, store them at ambient or chilled temperatures, and ship them interstate with zero breakage.

The Meat Industry (Retail Presentation)

- The Problem: While “cryovac” (hard vacuum) is best for storage, the purple colour of oxygen-starved meat can look unappealing to the average supermarket shopper who associates “red” with “fresh.”

- The Solution: By using a gas flush, butchers can create retail-ready packs where slices of meat sit loosely and attractively in the tray, retaining their colour and shape while still being hermetically sealed against contamination.

The Henkelman Advantage: Sensor vs. Time Control

This is the critical differentiator for buyers. Many budget vacuum packers offer Gas Flush, but they operate on a time control system. The machine guesses how much gas to inject based on a timer (e.g., “inject gas for 3 seconds”).

This is inaccurate. If the gas bottle pressure changes or the bag size varies, the amount of gas inside changes. You end up with some bags that are too puffy (and burst) and others that are under-filled (and crush the product).

Henkelman machines utilise Sensor Control (standard on the Advanced Control System or ACS).

- How it works: The machine uses a precision sensor to measure the pressure in millibars. You program the machine to pull a vacuum to 99.8%, and then inject gas until the pressure returns to exactly 500 millibars (or your chosen setting).

- The Benefit: Every single cycle is identical. Whether you are packing one bag or ten, the machine injects the exact volume of gas required to reach the target pressure. This guarantees consistent packaging quality, which is vital for brand reputation on the shelf.

Don’t Crush Your Profits, Get a Henkelman Machine

In a competitive market, presentation is everything. If your product looks crushed, tired, or discoloured, it stays on the shelf.

Standard vacuum packing is an incredible tool for preservation, but it has its physical limits. Henkelman’s Gas Flush technology removes those limits, allowing you to combine the hygiene and shelf-life benefits of vacuum sealing with the gentle handling required for premium, delicate products.

Whether you are looking to extend the life of your artisan breads, streamline your salad bar prep, or ensure your smoked fish arrives at the customer’s door in perfect condition, MAP is the invisible ingredient that adds value.

Ready to find the right atmosphere for your product?

Henkelman Australia offers Gas Flush (MAP) options across our Table-top, Floor-standing, and Industrial ranges. Contact our team today to discuss which gas mixture and machine configuration will best suit your business.